Business is a significant economic institution that affects the life of everyone. Therefore business should be a part of everyone’s knowledge. We get associated with business from birth to death. Whether one plans to own a business or merely be a: worker in an enterprise, one needs to have a knowledge of numerous things concerning the many complicated activities of a business such as insurance, advertising, store display, shippingand transportation, employee relations and regulations, law and governmenta1 regulations, and public relations. It can be assumed that people study business for a number of reasons. Some plan to make a lucrative career in business. Others are curious to learn how the business system affects them in their roles as wage-earners, shareholders, suppliers or consumers.

Some specific reasons for studying business are outlined below:

(l) Career Selection: The study of business enables a person to consider varying occupational possibilities, the bulk of which are in the private sector. There are similar career opportunities found in government ministries and departments, but business gives more practical opportunity of handling the development of career problems. The study of business exposes students to the opportunity of considering various jobs, the work required, rewards involved, and the necessary training preparations needed. Study of business builds a lot of confidence into the student because he sees himself capable of handling the problems and challenges of jobs and situations.

(2) Business Ownership:Some students have the capacity to develop themselves through the challenges of operating their personal businesses. Study of business is a right first step totake in setting up one’s own business. Management becomes more crucial when a person is investing his personal funds.

(3) Facing the Problems’ of Society: As soon as one gets into business, one is faced with crucial societal problems such as employment and its rewards, taxation, the price level, inflation, industrial safety, communications, transportation and so on, A business career is likely to put a student in a position of responsibility quicker than most other occupations. In the area of holding politicalpositions in Nigeria, independent business men and women are more favoured.

(4) Satisfaction: Business as a discipline of study has the following attractions:

(i) The reward of studying business can be as exciting and rewarding as engineering, chemistry, law or physics. Opportunities abound in business for innovations and new discoveries, profits can be made and the development of society and the economy ensured.

(ii) Business concepts are usually some of the dominant types of knowledge. Well-known patterns of employer-employee relations in business are being recently copied in government administration and educational establishments. Business has an unrivalled ability to communicate with large numbers of people, and business efficiency is the envy of other important economic and social institutions.

(iii) Wider Exposure: Business is an interdisciplinary subject. It depends on findings from science, psychology, economics, sociology and anthropology. Specialized business concepts have been distilled from these and many other subjects.

(iv) Practical Approach: Businessknowledge is tested by practice. Businessmen have developed advanced practical methods of assessing a firm’s performance, including accounting statements, budgets, quality control. Business can measure results just as a scientist does in a laboratory.

Questions and Discussions

What is a business enterprise?

Discuss the obligations of a businessman to different segments of the society. Are these obligations discharged properly in Nigeria?

Discuss the reasons for the study of business in universities.

References

Louis E. Boone and David L. Kurtz, Contemporary Business. Hinsdale, Illinois: The Dryden Press, 1976, p. 6.

Paul G. Hastings, Introduction to Business. New York: McGraw-Hill Book Company, 1968, p. 2.

Sir Frederick Hooper, Management Survey (rev. ed.). London: Sir Isaac Pitman and Sons ‘Ltd., 1961, p. 158.

Bayard O. Wheeler, Business: An Introductory Analysis. New York: Harper and Row, Publishers, 1968, p. 18.

Paul G. Hastings, Op. cit., pp. 4-5.

PRODUCTION

The Primary objective of every industrial organisation is to produce something and market what it produces in an efficient manner by legal and ethical methods so that the goals of the organisations are achieved in the long run.

Industrial organisations can be broadly divided into two types, namely, ‘manufacturing organisations such as factories, breweries etc. which produce physical goods as their output, and ‘service organisations such as hospitals, schools, air lines etc. which produce some service as their output. Thus, every industrial organisation produces either physical goods or some service. Production management deals with the different problem areas a production manager will be confronted with, in trying to produce the products in an efficient manner to achieve the goals of the organisation, and possible methods of solving these problems. The goals, the problems and methods of solution that apply to manufacturing organisations are, in general, different from those of service organisations. For example, the primary goal of a manufacturing organisation is to maximize its profits in the long run whereas the primary goal of some service organisations such as hospitals may be to provide maximum health care service to the community. Here, we concentrate on manufacturing organisations. However, the familiarity with the problem and methods of solution discussed here for manufacturing organisations can be used toanalyse the production management problems that arise in service organisations.

Production relates to other three main functional fields of business, namely, marketing, finance and personnel management, as can be seen from the following: marketing programmes of the company affect the demand for its products and therefore quantities to be produced, also the production policies affect the marketing and advertising programmes; the financial position and policies affect the facilities available for production and therefore types of products and quantities that can be produced, also production policies affect the financial position of the firm; industrial relations and personnel management policies affect the motivation and productivity of human resources and therefore affect the level of production. It can be easily seen from the above that the four main functional fields of business namely, production, marketing, finance and personnel are interrelated. Therefore, decisions on production policies cannot be taken in isolation, they must be taken in conjunction with the policies of other departments.

PRODUCTION SYSTEMS

1. Definition of Production

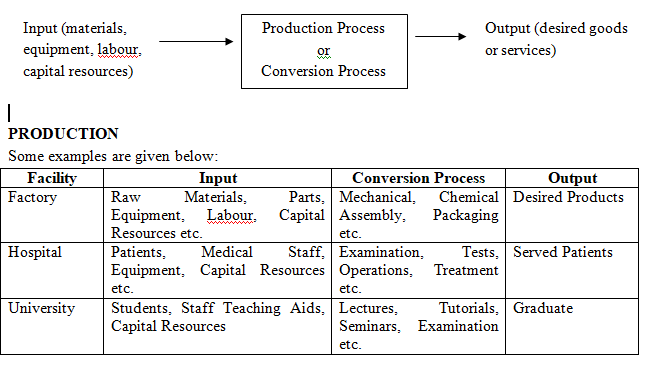

Production can be defined as the process by which goods or services are created. That is, production is the process by which a set of inputs is converted into a set of desired outputs. Clearlythe inputs and the conversion process; depend on the desired output. Diagrammatically, production can be represented by the following:

| Input (materials, equipment, labour, capital resources) |

| Output (desired goods or services) |

| Production Process or Conversion Process |

2. Types of Production Processes

At times, the word “production” and “manufacturing” are quite often used interchangeably. But there is a distinction. This is because production has much broader meaning and it includes all activity wherein something of value is created. That is, production, as pointed out early, includes services such as those provided by hospitals, universities, insurances, banks and so on. Manufacturing on the other hand, refers to production of tangible goods such as books and food products along with many thousands of other items produced for individual and business uses. In this section we shall briefly look into methods by which materials are produced or manufactured into the items that people want. These methods are known asproduction processes.

There are many kinds of production processes, some very simple, others very complex. The simplest forms of production are those which involve one or more persons making a product by hand with little or no equipment. Examples include one man carpenter-shop, basket weavers, and pottery making.

A complex production is one that is involved with machinery and automatic controls. This type of production requires large expenditure on plant and equipment. Examples are an oil refinery, and a modern, steel-making plant. One may also classify production processes according to the type of change made in materials being “converted” to the required product. Accordingly we have the following production processes:

(a) Extractive Process: This is the case where the basic production process consists of extracting substances from the earth, the air, or the sea. Examples are mining of coal, iron ore and gold; drilling for petroleum; and extracting of salt from sea-water. Fishing and farming may also be called extractive industries.

(b) Analytic Process: This is the case in which a basic substance is broken down into a number of other materials, in which the product may bear little resemblance to the original substance. Examples include petroleum refining and timber milling.

(c) Fabricating Process: This process is sometimes called a converting process. This refers to what is done when a material has its form chal1ged by being machined, woven, cut up, pressed, finished, or treated in some other manner. Examples include manufacturing of clothes, and shoes.

(d) Synthetic Process: In some industries, a number of materials are combined to form a single product. For example, in themanufacture of steel, glass and nylon, the final products are quite different from the original constituents because of physical or chemical changes. When separate parts, which have already been manufactured, are combined together without physical or chemical changes, you have what is referred to as assembly process.

3. Production Systems

Production is defined above as the conversion of a set of inputs into a set of outputs through a conversion process. In the conversion process, inputs go through a series of operations. In a manufacturing organisation, the operation may be mechanical, chemical, assembly, inspection and control, packaging, shipping etc. The conversion process together with receiving of inputs and shipping of outputs is called “production system”. There are two main production systems in manufacturing organisations namely, “continuous production system”, and “intermittent production system”.

(a) Continuous Production System

Continuous production systems are used for products that are produced continuously due to their high and stable demand. For example, automobile manufacturing plants, refineries, breweries etc. use continuous production systems, because due to high and stable demand for their products they are produced continuously.

Continuous production systems have the following characteristics:

(i) They produce large quantities of a few products (i.e. standard products).

(ii) Facilities and equipment are standardized according to the few products produced. That is the equipment which is specially designed to process the few products that may be used.

(iii) A fixed sequence of operations is used. Usually, equipment is arranged on the factory floor according to the requiredsequence of operations. That is, arrangement of equipment is according to the sequence of operations to be performed on the inputs for the product being produced. This type of arrangement of equipment is called a “product layout’: or “line layout” as the layout of equipment depends on the products being produced.

(iv) Continuous flow transportation facilities are used according to the sequence of operations.

(v) There is low storage time between operations, and items are taken from storage to operations according to first-in-first-out (FIFO) priority rule.

(b) Intermittent Production Systems

Intermittent production is characterized by the fact that a given product is manufactured intermittently and not continuously. Intermittent production is used for products where demand is so low that they need not be produced continuously. For example, if one month’s demand can be met by production in one or two days, the product may be produced only one or two days per month and stocked to cater for the demand. That is, these products appear in the production schedule for a limited period of time and then drop out and may reappear again after some time.

Intermittent production systems have the following characteristics:

(i) Produces small quantities of a large number of products.

(ii) Equipment must be, flexible enough so , ‘ that they can be adapted to process a wide variety of products

(iii) No single sequence of operations is appropriate due to wide variety of products being produced.

(iv) Transportation facilities between operations must be adaptable to a variety of routes for different products.

(v) There is considerable storage between operations.

(vi) Since there is no single sequence of operations, equipment are grouped together or departmentalized according to the functions (or operations) they perform. Here the layout of equipment is process oriented and it is called “process layout” or “functional layout”.

Manufacturing organizations generally use a combination of product layout and process layout; fabrication of parts generally following process layout and assembly operations following product layout.