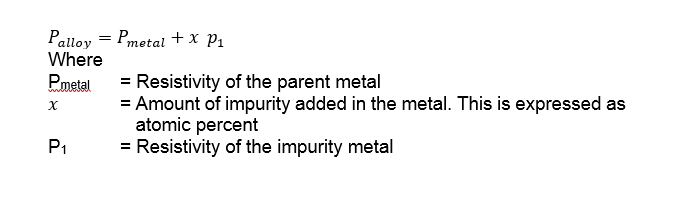

The electric current flows due to the movement of electrons. But sometimes, the electrons experience opposition to their movement through the conductors. This happens when the electrons come across valencies, impurity atoms or other lattice defects. This property of the conductor, due to which it opposes the flow of current, is known as resistivity of a metal. The following are the main factors which affect resistivity of metals:

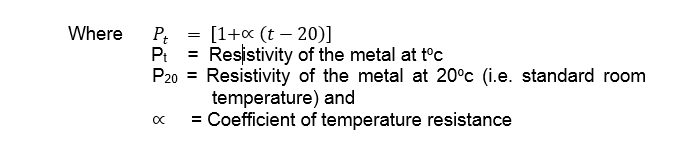

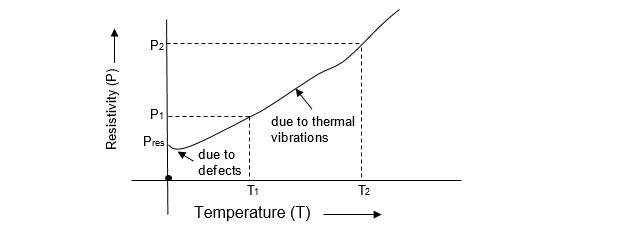

It may be noted that the metals have positive value of coefficient of temperature resistance. At high temperature, the thermal vibrations of the atoms increase. This reduces the motion of electrons through the conductor. Or in other words, the resistivity of a conductor increases with an increase in temperature. But the resistivity of insulators, semiconductors and electrolytes decrease with rise in temperature.

Fig. 14 shows the variation of resistivity with temperature for a pure metal. As seen from this diagram, the resistivity at low temperature exists due to defects in the micro structure of a pure metal. In general, the resistivity of a metal increases with the increase in temperature. The increase in resistivity happens mainly due to increase in thermal vibrations.

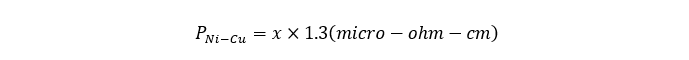

Thus if nickel is added to copper, the resistivity of copper goes up by 1.3 micro-ohm-cm for each atomic % addition of nickel. This may be expressed by the following relation.

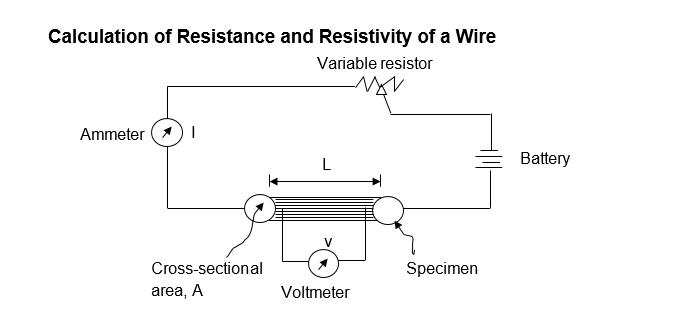

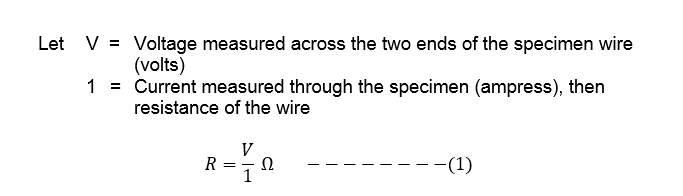

Fig. 15 shows a circuit indicating a wire connected to a battery through an ammeter land a variable resistor. A voltmeter (v) is connected across the two ends of the specimen wire to measure the voltage drop. The variable resistor is to limit the current in the circuit. This circuit can be used to measure the resistance of a wire.

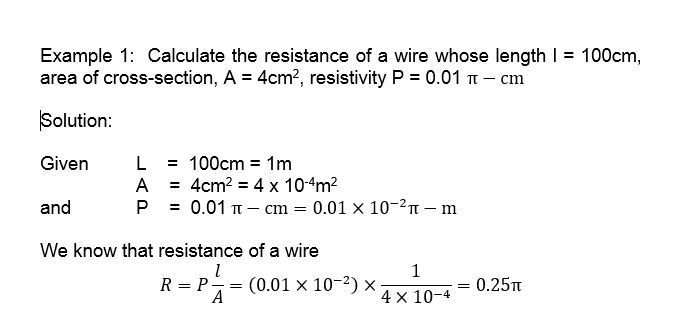

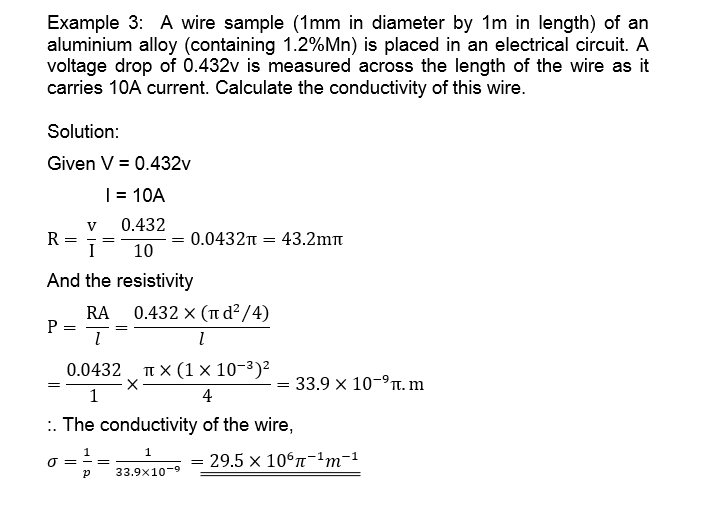

The resistance is expressed in ohms (). The resistance of a wire can also be calculated from the dimensions of the wire provided the resistivity of a material (of which the wire is made of) is known.

This is shown below

Let P = resistivity of a wire

L = length of a wire (m)

D = diameter of the wire (m)

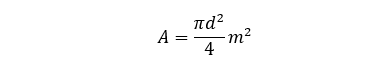

Then area of cross-section of a wire,

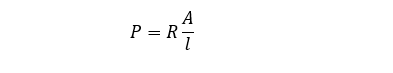

and resistance of a wire

Notice that resistivity is expressed in

Thus if resistance is in ohms, A in metre2, l in metres, then resistivity is in (or ohms – metre)